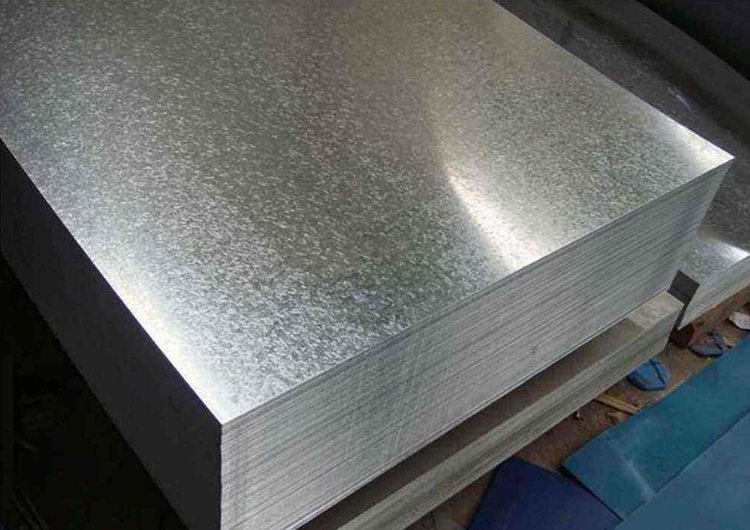

In the modern industrial and construction sectors, material selection directly impacts project quality, durability, and cost-effectiveness. Galvanized steel plates, as specially treated steel products, have become the preferred choice for numerous industries due to their exceptional corrosion resistance, high strength, and versatility. This article explores the advantages, applications, and reasons why galvanized steel plates are the ideal solution for your projects.

Galvanized steel plates are manufactured by either immersing regular steel plates in molten zinc or applying a uniform zinc coating through electrolysis. This process not only retains the high-strength properties of the original steel but also endows it with superior corrosion resistance, significantly extending the material's service life.

The zinc coating protects the steel in two ways: first, it acts as a physical barrier separating the steel from air and moisture; second, when the coating is locally damaged, zinc acts as a sacrificial anode, corroding preferentially to protect the underlying steel. This dual protection mechanism ensures galvanized steel plates maintain stable performance in various harsh environments.

Galvanized steel plates offer 5-10 times better corrosion resistance than ordinary steel, particularly excelling in humid, rainy, or coastal environments with high humidity, effectively resisting rust and corrosion.

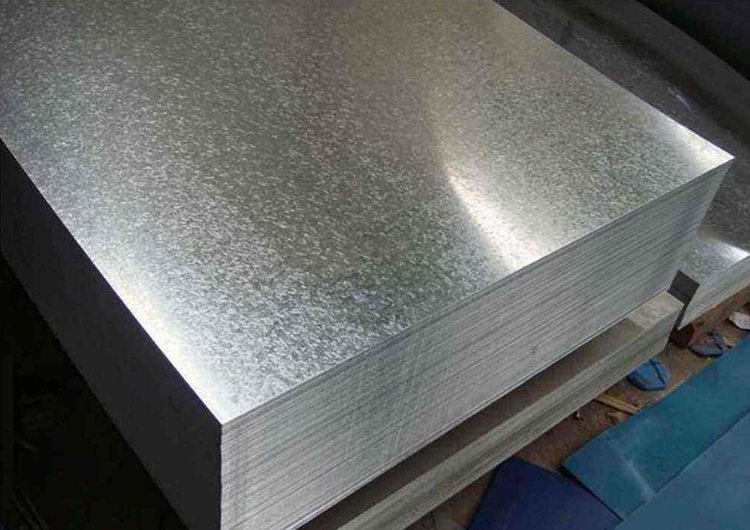

In general environments, galvanized steel plates can last 20-30 years; in dry conditions, their lifespan can exceed 50 years, significantly reducing maintenance and replacement costs.

The galvanizing process does not affect the original mechanical properties of the steel, which retains its high strength, excellent toughness, and formability to meet various structural design requirements.

While the initial investment in galvanized steel plates is slightly higher than ordinary steel, considering their extended service life and minimal maintenance requirements, the overall cost is actually lower, making them an extremely cost-effective choice.

Zinc used in the galvanizing process is a recyclable material, aligning with modern green environmental protection concepts. Additionally, extending material service life itself represents resource conservation.

The versatility of galvanized steel plates has led to their widespread use across multiple industries:

Roofing and wall systems

Steel structural frameworks

Guardrails and fencing

Pipe and ventilation systems

Bridge and viaduct components

Automotive parts

Home appliance casings and components

Storage racks and logistics equipment

Agricultural machinery and equipment

Power transmission towers

Communication base stations

Container manufacturing

Railway and subway facilities

We are committed to providing high-quality galvanized steel plate products to meet your various project needs:

Strict Quality Control: Every step from raw material selection to galvanizing processes undergoes rigorous testing to ensure products meet international standards.

Diverse Specifications: We offer products with different thicknesses, sizes, and zinc coating thicknesses to meet your personalized requirements.

Professional Technical Support: Our team of engineers can provide professional material selection advice and solutions based on your project characteristics.

Timely Delivery: Efficient production and logistics systems ensure your projects progress on schedule.

Competitive Pricing: Directly connecting with manufacturers eliminates intermediate links, providing you with the most cost-effective products.

Whether for large construction projects, industrial manufacturing, or agricultural facilities, galvanized steel plates deliver durable, reliable material solutions. Choosing galvanized steel plates means selecting the perfect combination of durability, economy, and environmental friendliness.

Contact us now for exclusive quotes and technical consultations, and let galvanized steel plates add value to your projects!